Industrial Standards For Charger Equipment

Part of Chapter Utility Practices: Standards and Codes

Video

NEMA STANDARDS

9.4.1

PE 5, PV 5

9.4.1.1

NEMA Standard PE 5, “Utility Type Battery Chargers,” is the principal specification covering the products discussed in this book. PV 5 is an older version, now retired.

PE 7, PV 7 (Communications Chargers)

9.4.1.2

Standard PE 7 covers chargers for communication-type batteries. The chargers discussed in this book meet most of the requirements of PE 7, but they haven’t been tested to verify compliance with the EMI portions of the standard (note, however, that the AT10.1 , AT30, and ATevo meet the EMI standards for CE conformity). PV 7 is an older version, now retired.

RI 2 (You’re kidding, right?)

9.4.1.3

RI 2 is a really, really old version of the Utility Type Charger standard. Up until about 2000, it would still appear in customers’ specifications, especially with regard to production testing, which was unnecessarily time-consuming. We’re happy to see it disappear.

NEC (NFPA-70)

9.4.2

The NEC (National Electrical Code) covers a lot of territory. Our primary concern is with the requirements for wire sizing, both for internal charger wiring and for interfaces with field wiring.

SURGE PROTECTION

9.4.3

ANSI/IEEE C37.90, Surge Withstand Capability

9.4.3.1

This standard defines, among a lot of other things, the test requirements for oscillatory surge withstand capability. The standard is referenced also by the NEMA standard, PE 5.

ANSI C62.41, Guide on Surge Voltages

9.4.3.2

C62 sets standards for the testing and performance of surge suppression devices, which includes the MOV (metal oxide varistors) used for surge protection in the input and output circuits of HindlePower products.

SAFETY STANDARDS

9.4.4

UL 1012, UL 1564, CSA 22.2, & CE

9.4.4.1

The complete HindlePower AT line of industrial chargers is certified by CSA to CSA 22.2. They are also certified by CSA, as a NRTL (National Recognized Testing Laboratory), to meet the requirements of UL Standard 1012, “Power Units Other Than Class 2,” and UL standard 1564, “Industrial Battery Chargers.”

The AT series meets the requirements of the CE Low Voltage Directive, the EMC directive, and the pertinent EMC standards. HindlePower will provide a Declaration of Conformity for equipment that must meet CE requirements. This is an option that must be ordered separately.

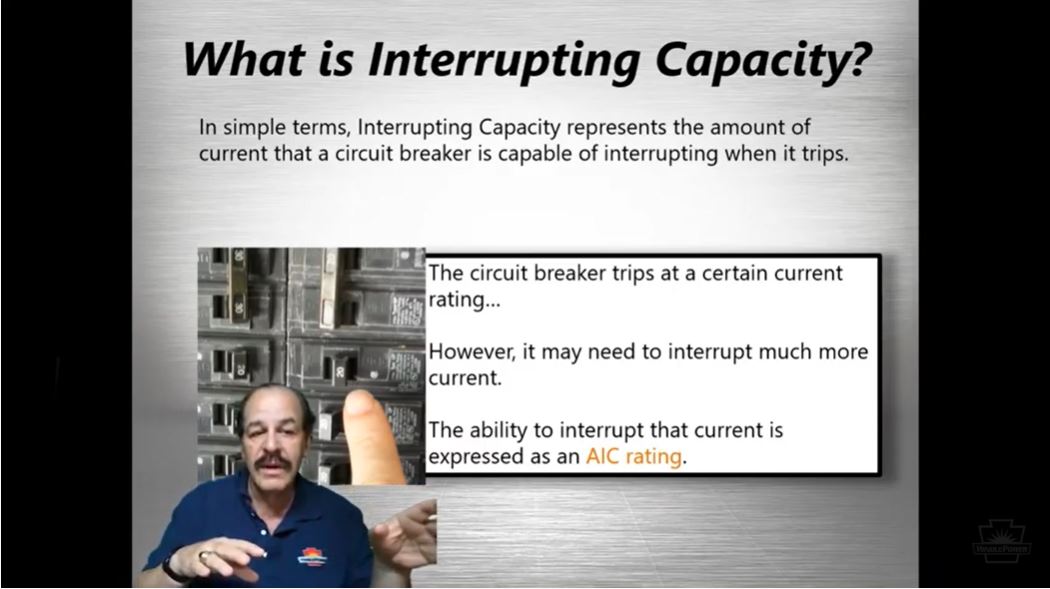

CIRCUIT BREAKERS

9.4.5

UL 489, NEMA AB-1, & UL 508

9.4.5.1

All dc output circuit breakers are UL listed to UL 489 and meet the requirements of NEMA AB-1. DC circuit breakers rated for 100 A trip or lower have an ampere interrupting capacity (AIC) of 5,000 A. Breakers rated over 100 A trip have an AIC of 10,000 A or higher, depending on the circuit breaker frame size and trip rating. DC breakers with higher AIC ratings are available on special order.

All standard ac input breakers through 100 A trip rating are magnetic/hydraulic appliance controllers, UL recognized to standard UL 508, with an AIC of 5,000 A.

Standard ac input breakers rated over 100 A trip are thermal/magnetic breakers, UL listed to UL 489, with AIC of 10,000 A or higher, depending on the circuit breaker frame size and trip rating. AC circuit breakers with higher AIC ratings are available on special order. In addition, thermal/magnetic circuit breakers listed to UL 489 are optionally available for trip ratings under 100 A.

TRANSFORMERS

9.4.6

ANSI C57 & NEMA ST20

9.4.6.1

Transformers and inductors meet ANSI C57 and NEMA ST20 standards. All magnetic components used in HindlePower products are manufactured using a UL-recognized class 200 or class 220 insulation system, File E-75663. The design temperature rise is typically 125 °C.

INTERNAL WIRING

9.4.7

In the SCR/SCRF battery charger, standard internal wiring is PVC to UL 1015 or equal, rated 105 °C, or XLPE* , rated 125 °C. Internal wiring in the AT charger series is primarily XLPE. Wire sizing is based on the NEC wire ampacity ratings but is modified where appropriate to account for the higher temperature rating of XLPE wire. Also, the NEC rates wire ampacities based on an ambient temperature of 30 °C; we adjust wire sizes to account for the higher operating ambient temperature of 50 °C.

Switchboard class wiring insulation is optionally available for the SCR/SCRF charger. This is frequently designated as SIS wiring. Most wire manufacturers now supply XLPE insulation to meet this requirement.

Instructors

Art Salander, Senior Life Member – IEEE

Sr. Applications Engineer / Business Development

HindlePower, Inc.